The automotive enterprise has seen exquisite adjustments through the years, driven by way of technological improvements. One such development is using rigid published circuit forums (PCBs).

These PCBs play a crucial role in present day automobiles, allowing numerous features and enhancing performance. Nowadays, one-of-a-kind PCB circuit forums affect and exchange each issue of our lives. If you need to do enterprise on this place, please contact Kingsun PCB.

In this text, we can explore the modern packages of rigid PCBs inside the automobile industry and apprehend how they contribute to the improvement of smarter, safer, and extra efficient cars.

Introduction to Rigid PCBs

Rigid PCBs are a form of circuit board that doesn’t bend or flex. They are made from a stable substrate material, generally fiberglass, that gives structural stability and support for digital components. Rigid PCBs are extensively used in many industries, which includes customer electronics, telecommunications, and, drastically, car.

Importance of Rigid PCBs in Automotive Industry

In the car industry, rigid PCBs are important due to their durability and reliability. Vehicles operate in harsh environments, which includes excessive temperatures, vibrations, and publicity to moisture. Rigid PCBs can face up to those situations, making them best for automotive programs. Additionally, their capability to assist complex circuits and excessive factor density makes them suitable for modern-day car electronics.

Applications of Rigid PCBs in Vehicles

Engine Control Units (ECUs)

One of the number one programs of rigid PCBs in motors is in the engine manipulate units (ECUs). ECUs are accountable for coping with numerous engine capabilities, inclusive of gasoline injection, ignition timing, and emission manage. Rigid PCBs provide the necessary structural integrity to support the complicated circuitry required for these functions. They ensure reliable overall performance beneath the hood, wherein temperatures and vibrations can be severe.

Infotainment Systems

Modern motors come prepared with advanced infotainment systems that provide a number of capabilities, inclusive of navigation, audio, video, and connectivity. These systems depend on rigid PCBs to aid the excessive-density circuits needed for processing and showing records. Rigid PCBs also help in lowering electromagnetic interference, ensuring clear audio and video alerts.

Advanced Driver Assistance Systems (ADAS)

Advanced motive force help structures (ADAS) have become more and more common in current motors. These structures consist of features like adaptive cruise manipulate, lane departure caution, and automatic emergency braking. Rigid PCBs are used inside the sensors and control units that energy those structures. Their reliability and capability to deal with excessive-pace information processing cause them to best for ADAS packages.

Lighting Systems

Automotive lighting systems have advanced considerably, with LED and adaptive lighting becoming the norm. Rigid PCBs are used within the manage circuits of these lighting fixtures structures. They provide the essential aid for LED drivers and other additives, ensuring green and dependable lights. Rigid PCBs also assist in managing warmth dissipation, which is vital for the sturdiness of LED lights.

Powertrain Control

The powertrain manage gadget in a car consists of additives like the transmission manipulate unit (TCU) and hybrid manage unit (HCU). These units manage the electricity transport from the engine to the wheels and cope with the integration of electrical electricity in hybrid automobiles. Rigid PCBs are used in those manage devices to make certain particular manipulate and efficient power control.

Safety Systems

Safety is a top priority in the automotive enterprise. Rigid PCBs play a critical role in numerous protection systems, along with airbag manage devices, electronic stability manipulate (ESC), and anti-lock braking systems (ABS). These systems require dependable and speedy-appearing circuitry to function effectively. Rigid PCBs offer the necessary guide and reliability to ensure those safety systems work flawlessly.

Connectivity and Communication

With the upward push of related motors, the want for robust communique systems has multiplied. Rigid PCBs are used within the modules that cope with automobile-to-vehicle (V2V) and automobile-to-infrastructure (V2I) communique. They make certain reliable information transmission, permitting features like real-time site visitors updates, far flung diagnostics, and over-the-air (OTA) updates.

Electric Vehicles (EVs)

The shift towards electric powered vehicles (EVs) has brought new demanding situations and opportunities for inflexible PCBs. EVs require advanced battery control structures (BMS), motor manipulate devices, and charging structures. Rigid PCBs are used in these applications to manipulate electricity distribution, display battery health, and control the electrical drivetrain. Their reliability and potential to deal with excessive energy hundreds make them vital for EVs.

Benefits of Using Rigid PCBs in Automotive Applications

Durability

Rigid PCBs are designed to face up to harsh conditions, making them ideal for automotive packages. They can bear severe temperatures, vibrations, and exposure to moisture with out compromising performance.

High Component Density

The capacity to support high issue density is some other benefit of inflexible PCBs. This allows for greater complex circuits in a smaller space, which is essential for contemporary automotive electronics.

Reliability

Reliability is crucial in car packages, in which device screw ups will have critical outcomes. Rigid PCBs offer dependable performance, ensuring that essential systems like engine manipulate, safety, and ADAS perform without issues.

Heat Management

Rigid PCBs are effective at managing warmth dissipation, that is critical for components like LEDs and energy electronics. Proper warmness control guarantees the longevity and performance of these components.

Cost-Effectiveness

While inflexible PCBs may have a better initial fee in comparison to different sorts, their sturdiness and reliability result in lower protection and alternative prices over time. This makes them a value-effective preference for automobile applications.

Challenges in Using Rigid PCBs in Automotive Industry

Design Complexity

Designing rigid PCBs for automobile programs may be complex due to the excessive issue density and the need for sturdy performance. Engineers have to carefully recall factors like sign integrity, thermal management, and mechanical pressure.

Environmental Concerns

The production and disposal of rigid PCBs could have environmental influences. The automobile industry is working toward more sustainable practices, but managing the environmental footprint of inflexible PCBs remains a mission.

Integration with Other Systems

Integrating rigid PCBs with different car systems, together with flexible PCBs and wiring harnesses, can be challenging. Ensuring seamless communique and reliable connections among exclusive systems is critical for basic vehicle overall performance.

Future Trends and Innovations

Advanced Materials

Researchers are exploring new materials for rigid PCBs that provide higher overall performance and sustainability. Materials like ceramics and advanced composites may want to provide improved thermal management and environmental benefits.

Miniaturization

As cars come to be greater advanced, there is a trend closer to miniaturization of digital additives. Rigid PCBs will want to assist even better issue densities whilst maintaining reliability and performance.

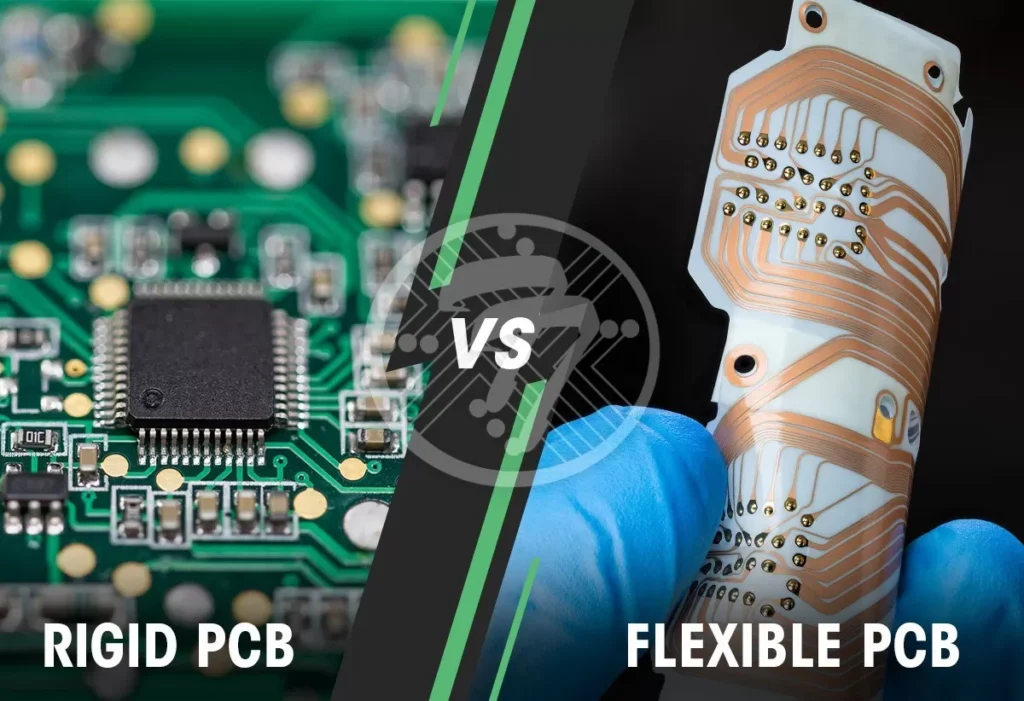

Integration with Flexible PCBs

Combining inflexible and flexible PCBs in hybrid designs can offer the fine of both worlds. These hybrid PCBs can provide the structural support of rigid PCBs and the flexibility needed for complex shapes and actions.

Enhanced Connectivity

With the rise of 5G and the Internet of Things (IoT), automobiles would require even extra advanced connectivity answers. Rigid PCBs will play a important role in assisting those technologies, enabling faster statistics transmission and advanced communication.

Conclusion

Rigid PCBs are a critical component in the automobile industry, supporting a wide range of programs from engine control to advanced motive force help structures. Their sturdiness, reliability, and capability to aid complex circuits make them ideal for current motors.

As the automobile enterprise maintains to evolve, inflexible PCBs will play an critical position in driving innovation and enhancing automobile overall performance. With improvements in materials, miniaturization, and connectivity, the destiny of rigid PCBs in the car enterprise appears promising.